Automobile knowledge sharing: How to adjust the cable clutch, you need to pay attention to the following methods

Release Time:

Nov 15,2023

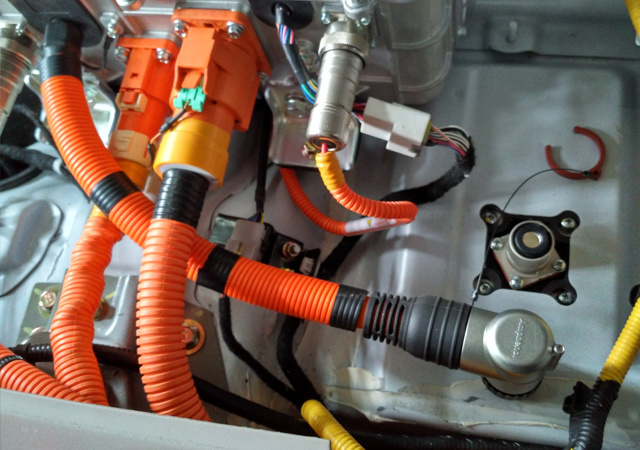

The clutch is the connection part between the engine and the transmission. The clutch action and gear shifting have a direct impact, so the clutch requires regular maintenance and adjustment. During use of the clutch, it should be checked regularly to see if it needs to be replaced.

The clutch is the connection part between the engine and the transmission. The clutch action and gear shifting have a direct impact, so the clutch requires regular maintenance and adjustment. During use of the clutch, it should be checked regularly to see if it needs to be replaced. If a gearbox part fails, it should be repaired in time. Main content: Adjust the shape of the clutch (split clutch) according to your own car model; determine the transmission ratio, engagement gap and adjustment method based on the actual driving conditions of the car and the internal wear of the gearbox.

1. When servicing a car, first fix the clutch pressure plate (i.e. half-clutch mechanism) on the chassis of the car and step on it with your feet to make the clutch spring rod contact the shaft hole and the tightness is appropriate.

When the tension of the clutch pressure plate spring elastic rod (i.e. axial force) is released, the clutch pressure plate comes into contact with the shaft hole. At this time, the cam on the clutch pressure plate also moves to the center of the shaft hole accordingly, and its angle is 90°. about. Then press it gently with your hands to make it align with the shaft hole without loosening. Then push the clutch mechanism by hand to make the gap between the clutch pressure plate and the wheel hub bearing surface and the bearing appropriate. Make the axle hole the same clearance as the car's pin hole, and then install the axle pressure plate onto the car's bearing. Tighten the axial force bolt to match the half shaft with the shaft so that the lubricating oil in the bearing seat flows through the clutch pressure plate and the shaft hole of the half clutch mechanism. Finally, install it from the car chassis and screw the locking nut onto the clutch pressure plate and tightening shaft (during maintenance, tighten the above bolts). After installation, tighten the pressure plate nut and shaft hole bolt; then measure the threaded hole diameter of the bearing seat. If the cam clearance of one shaft hole still cannot meet the requirements after the vehicle is repaired, it needs to be adjusted: use hand tools to adjust the gap between the transmission pressure plate (pressure plate) and the shaft hole to the specified size. If these two methods are not available, the gap between the pressure plate pin hole and the shaft hole can be adjusted appropriately to make it just right. However, during assembly, care should be taken to ensure that the clutch pressure plate will not be damaged prematurely when the vehicle starts smoothly; vice versa. To be avoided. At the same time, it also causes the gear rotation to vibrate, causing mechanical accidents such as clutch friction plates to break and wear. This requires automobile maintenance personnel to conduct inspections and adjustments based on the actual situation and operating conditions of the vehicle. The specific method is as follows: before car maintenance, the clutch pressure plate should be cleaned first to remove carbon deposits, rust and other foreign matter; check whether its engagement gap meets the requirements. If it is not qualified, it needs to be repaired or replaced with a new half-clutch mechanism. The engine, gearbox assembly and transmission components must be placed in a vibration-free state; when the wear of each part allows, make adjustments; adjustment method: have technicians make adjustments.

2. After starting the engine, first pull up the mating surface of the clutch pull rod and the pressure plate to the highest point. At this time, you should immediately depress the clutch pedal. At this time, you can check whether the segregation amount is normal.

If the segregation exceeds 60%, the pressure plate gap can be adjusted until it meets the requirements. When replacing the clutch pull rod, you should first pull out the bolt head of the pressure plate, and then use your hands to tighten the contact area between the bolt and the pressure plate mating surface. When the amount of segregation exceeds 70%, adjustment should be made. If there are traces of friction on the pressure plate, it means that the gap between the pressure plates is too large or does not match. At this time, the clutch pull rod should be replaced, otherwise the shaft pin should be adjusted. The gearbox lining must be replaced when it reaches 70% or above to ensure the correct transmission ratio of the gearbox. However, it should be noted that if the new gear cannot be immediately put into normal driving, it must be replaced first and then refueled before starting the engine. Since the automatic transmission has no response to the engine, after starting the engine, you must first gently lift the clutch pedal at idle speed and then lift it up again. This can ensure that the clutch works normally and the engine starts smoothly without abnormal noise from the clutch; and It can make the rotor of the high-speed rotating part of the engine generate strong impulse to avoid accelerated clutch wear!

3. Place the clutch plate on the pressure plate at one end or in the groove where the pressure gauge is installed.

Use a dipstick to measure the distance between the centerline of the pressure plate and the flange to be 1.5-2.0 mm. Secure the pressure plate to the flange. The minimum flange of the clutch end pressure plate must be parallel to the flange. Otherwise, the pressure gauge will be damaged to a great extent and the pressure gauge should be replaced. Place the adjustment handle in the P position. Make the flanges on the pressure plate parallel and press into the grooves. Then adjust the 1-2 gear gap to make the clutch plate recessed by about 1.5-2 mm.

4. When the angle between the top surface of the pressure plate and the pressure wheel shaft is less than 90 degrees, the cam cover cam shall be against the cam bearing body;

When the angle between the top surface of the pressure plate and the pressure wheel shaft is less than 90 degrees, the height of the cam is the height of the clutch, assuming that the cam is pressed against the cam bearing body. The clutch pedal is generally placed flat. The area that needs to be adjusted after the clutch pedal is depressed is the clutch engagement gap. The car can only be put into gear when the clutch is in neutral. When shifting gears, you need to depress the clutch to the bottom, otherwise it may cause serious damage to the gearbox or cause driving safety hazards. Therefore, it is very necessary for us to check the clutch frequently. We can also use the automatic transmission as a machine in normal times, so that we can have a better driving experience. Generally, automatic cars use CVT or AT transmission to drive. So how should we ensure that the relationship between the gearbox and the clutch is relatively close?

5. During the adjustment process, the non-reverse tooth correction method should be used.

First, when accelerating and decelerating in P gear to no-load, the height and speed of the clutch pedal must meet the requirements. Then, depress the clutch pedal before engaging the gear, so that the car can drive slowly on the road without inverted forks and teeth. Then stop the car and let the engine run for 5-10 minutes. Check whether the clutch pedal is fully depressed. If you feel the clutch pedal is depressed but does not do it immediately, then the clutch is faulty. If the vehicle is driving very slowly, there is no guarantee that it will not stall. If it still does not stall, it means that the clutch cannot smoothly separate the clutch. Under normal circumstances, we cannot completely avoid the possibility of such a failure. of. Because it may be that our car's clutch needs to be repaired or replaced in time after it fails, otherwise it will affect our relationship with the service life of our car. This is something we ourselves should pay attention to.

6. When making an adjustment every 3,000 kilometers or so, first put the gear lever into gear and drive the car slowly for a few minutes to 1 to 2 minutes before turning on the ignition switch (starting the engine). At this time, if the reverse gear is engaged, it still cannot be engaged. The desired gear is enough.

If the upshift restriction still cannot be released when the reverse gear is engaged, the clutch needs to be adjusted again. At this time, the vehicle should be parked in place and wait for the shift lever or other normal operations. During use, due to fatigue, local overheating and loosening of internal metal fittings due to surface wear of the friction plate, camshaft and friction plate, the clutch mechanism will cause clutch gearing, and in serious cases, it may cause engine failure. Therefore, when using the clutch, attention should be paid to regular maintenance and adjustment.

Key words:

What Else Might You Learn?